Ford Super Duty

Truck Cap Fishing Rod Rack

2004 F250 4x4 XLT Sport Crew Cab

Click Here for a PDF version of this article

Every time we go fishing all the fishing poles end up in the bottom of the bed, underneath the folding chairs, tackle boxes, coolers, backpacks, and such.

So, I decided to come up with a rig where I could hang our fishing rods from the ceiling of my truck cap, up outta harms way.

I searched around quite a bit and there are quite a few fishing rod storage systems for trucks, SUVs, campers etc. Most of those were either really pricy or wasn't quite what I wanted.

I ended up designing my own setup and had a machinist buddy of mine make them up for me.

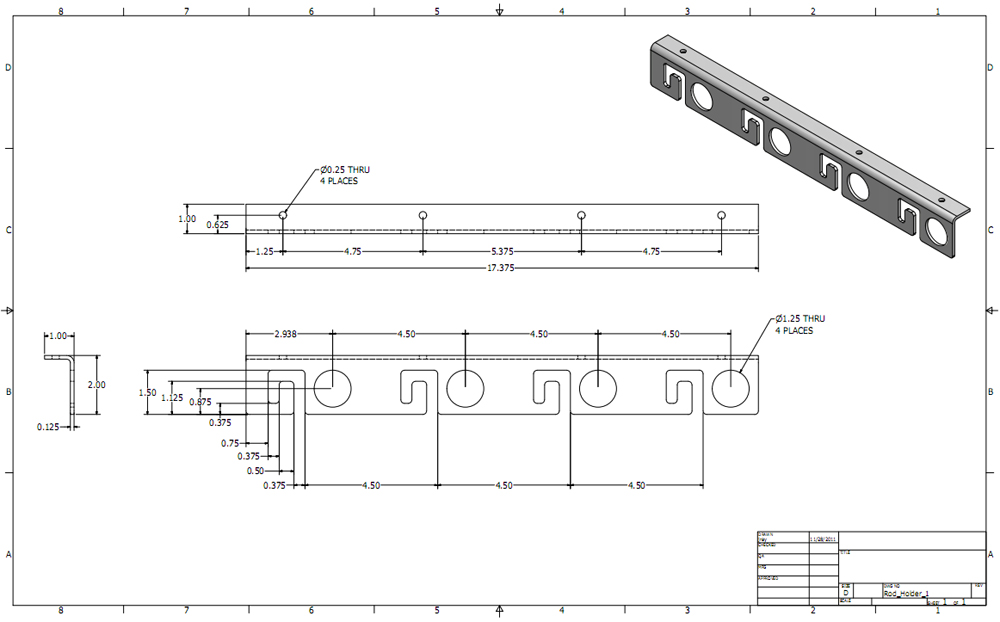

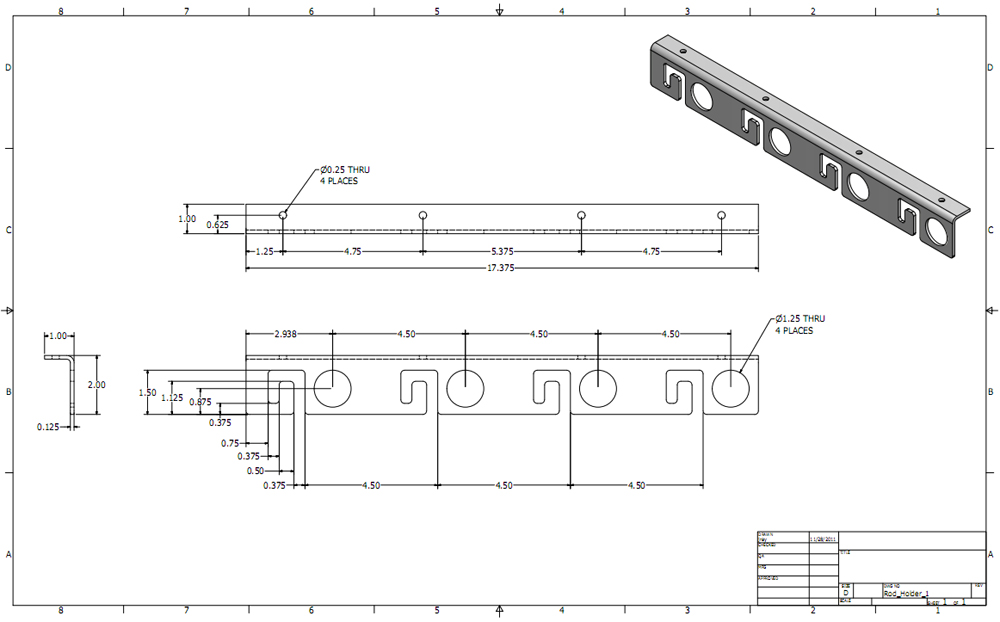

Below is the drawing. The rod rack requires two of these brackets. One mounted at the back facing one way and another mounted toward the front facing the other way. That will make more sense when you see the pics below.

Here's the brackets, made of aluminum and finished in yellow chromate.

Here's the test fit on the ceiling in my garage. Lookin' good so far!

You first insert this end into the round openings........

..... then you can insert the far end into the groove.

I wanted to be able to insert & remove the tip-end of the pole without having to climb into the truck. I also needed some way to resist them bouncing out while driving down the road. This design should accomplish both of those things.

One problem is that its made from aluminum, meaning it will likely scratch up the fishing poles while driving down the road. So, thanks to a great suggestion I got in my thread on FTE, I cured this problem with some plastic grommet strip.

I cut a piece 2-3/8" long which worked out well. I didn't fill in the full diameter because one of my poles wouldn't have fit.

Now for the slotted opening. I cut a piece 1-1/4" long and snipped it at 1/2" and 3/4" from one end, to allow it to fit around the bottom.

Like this.

All of the openings protected.

Another test fit. Looks like it'll work out.

Now that the parts seem to hold the fishing poles properly, its time for the hard part -- mounting it to the ceiling of my truck cap!

I noticed right off the bat that a large section of the ceiling in my top is dropped down about 3/4". I contacted the mfg of my top and they confirmed that I can drill into the dropped down section and use screws up to around 5/8" long.

I used a 7/64" bit and put a stop block at around 1/2". I drilled the holes and installed them with 1/2" self tapping screws.

Since the spacing in my garage, 48 inches, seemed to work well, I used that in my truck. I used VHB tape on the brackets for a couple reasons -- first, so I could install them and test them without drilling... second, to provide a little cushion between the top and the bracket.

Since two of our poles are longer than my truck bed, I installed these brackets on a little bit of an angle, to minimize how much of the pole had to bend at the front.

I may adjust the placement when the weather warms up to give it a little more rotation, but this works for now.

Here's the first test fit.

They don't hang below the opening at the rear

So, I drove around for a few weeks to test out the setup and I had three incidents of a pole falling out. Twice it was one of the longer (bent) poles and the third time is was a shorter one.

This was three incidents over a few hundred miles on some rough roads. Not bad but I don't want them to ever fall, so I took some short pieces of adhesive backed foam and installed them as shown in this pic. I cut the end to a point so that it would provide minimal resistance when installing/removing the pole. But, its enough to keep them secure if they bounce around while driving.

I drove around with them another couple hundred miles with no poles falling out so I declared victory.

If I were to get the brackets made again, I might run the horizontal part of the groove a little higher, and run the bottom part of the vertical groove a little lower. I think more height where the pole rests would keep them from popping out, even without the foam. I'm happy with it as-is though!

Questions or Comments? Email jmray@frontiernet.net