Bass guitar preamplifier in the Ampeg SVT tradition

Designing and fabricating the front panel

Prototype

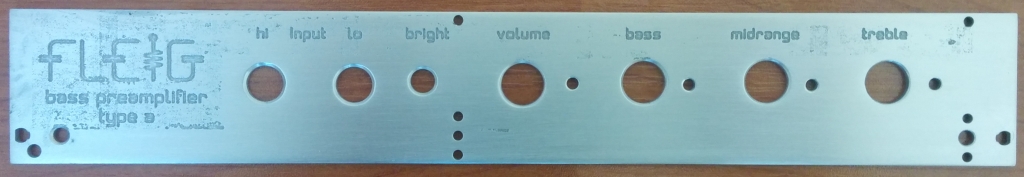

I designed the first version of the front

panel with Microsoft Visio 2003, and made it myself using

the front panel blank supplied with the Par-Metal

enclosure. I used a drill press and a step bit to

make the holes for the controls, and normal drills to make

the anti-rotation holes. It came out perfectly - all

the controls fit into the panel, and the panel fit the

enclosure. Here is my unlabeled hand-fabricated

panel:

Toner transfer / copper sulfate etching

experiments

However, I wanted professional-quality lettering for the

control labels. I spent quite a while attempting to do

this myself using the toner transfer technique and chemical

etching, but my test etchings did not achieve the quality of

result I was seeking. Here is one of my toner transfer

etching experiments, performed on my Fender Blackface

control panel wiring fixture/template. All the extra

holes are preexisting features of the scrap aluminum I used

to make the template. I wasn't able to get a high

enough toner density with my printer to prevent unwanted

etching of the background. I'm still enthusiastic

about the capabilities of the toner transfer and etching

process, but I need more time to refine my process. I'm

going to try again with a better printer on a future

project.

Front Panel Express

I reluctantly abandoned my efforts to do

the panel labeling myself, and used the Front

Panel Express design software and CNC fabrication

service to realize the front panel. Initially I was

not eager to use their proprietary design program to re-do

the panel. However, it turned out that the software

was not difficult to learn. The positions and dimensions

for the control holes, blind holes on the back side for

the anti-rotation tabs, and labels are easily entered and

refined. Since the Front Panel Designer (FPD) software is

optimized to feed into their fabrication process, the

designer can be confident that the panel will be

manufactured exactly as designed. The cost for each

feature is tabulated as the design proceeds, so you know

exactly what the panel is going to cost.

A few things I learned:

A few things I learned:

- Minimize the labeling costs by using single stroke

fonts. I originally designed my panel in Visio

using a modern TrueType font. However, this font

was not supported by the FPD software. Therefore

I chose the rather plain DIN17 single stroke font

using the 0.2 mm engraving tool. I was more than

happy with the appearance of the finished panel.

- Line art, and logos can be imported into FPD as HPGL plotter command files. I was able to copy-paste my line art logo (conceived by my wife) from Visio into the fabulous Inkscape open source vector graphics editing software, and export it as an HPGL file. This file was then imported into FPD, where it was only necessary to set the mirroring option to make it render properly. I chose the 0.4 mm engraving tool for the logo.

- Front Panel Designer can export the designs into

Autocad DXF files or Scalable Vector Graphics (SVG)

format files. After completing the FPD design, I

exported it as an SVG file and imported it into

Inkscape. I then created vector art for all the

controls, jacks, and knobs, so I could check the

appearance and positioning of all the

labels. During this process, I found that

a few labels would have been partially obscured by

toggle switch trim washers. I was then able to

adjust the size and position of these labels to

eliminate the obscurations. I enjoyed using

Inkscape so much that I spent effort than necessary to

make nice models of the chicken-head knobs and toggle

switches.

- FPD allows you to zoom the view as much as you like

to make sure the details of features appear the way

you want them to.