Plastic Ribbons

I have Plastic WW1 Victory Medal Ribbons as well as

others from WW2.

see

for an article on Ebay which talks of Plastic Ribbons. as of

12/06/2011

From a 1944 patent application by Joseph Wolf of the Wolf-Brown

Company.

The primary object of my invention is to provide a service ribbon or

campaign bar that is protected against wear and soil and at the same

time

may be removably attached either as a single unit or in multiple units

to a mounting bar without 30 supplemental fasteners.

Click here for

picture and text from Google

as of 10/03/2017 or look up patent number 2,392,351

Plastic Ribbons are as described in the patent,

this does not mean the ones that had a

plastic/nitrate

flim over the Ribbon that yellowed with age and which also cracked

easily.

Patented Jan. 8, 1946, 2,392,351, UNITED STATES PATENT

OFFICE,

2,392,351

CAMPAIGN BAR AND MOUNTING THEREFOR

Joseph Wolf, Beverly Hills, Calif., assignor to Sylvan Wolf, Los

Angeles,

Calif.

Patented Jan. 8, 1946, 2,392,351, UNITED STATES PATENT

OFFICE,

2,392,351

CAMPAIGN BAR AND MOUNTING THEREFOR

Joseph Wolf, Beverly Hills, Calif., assignor to Sylvan Wolf, Los

Angeles,

Calif.

Application January 29, 1944, Serial No. 320,231

1 Claim. (CI. 40—1.5)

The present invention relates to new and useful improvements in the

method of-constructing laminated ribbon campaign bars and to provide

for

their iriterchangeability of position on mounting bars when necessity

requires

their removal 6 from one mounting bar to another, or when a change of

position

on the same bar is necessary to maintain their order of precedence.

Both the Army and the Navy use service ribbons for their decorations

and medals during war- Iq time. The Army decoration service ribbons are

worn in one or more lines in the sequence of their importance starting

on the top row toward the center of the body and reading leftward,

followed

by medal service ribbons in the sequence earned, is When more than one

line of ribbons are worn, such lines will overlap.

Since the most distinguishing decorations for valor are sometimes

awarded

subsequently to those of a less distinguishing character, it becomes

necessary

to adjust the arrangement from left to right in order to conform to the

Army and Navy requirements of wearing decorations, service medals and

badges

in the prescribed order of precedence. . 25

The primary object of my invention is to provide a service ribbon or

campaign bar that is protected against wear and soil and at the same

time

may be removably attached either as a single unit or in multiple units

to a mounting bar without 30 supplemental fasteners.

Another object of my invention is to provide a laminated service

ribbon

or campaign bar resulting in-a single unitary article provided with

means

for interchangeably mounting the same on 35 a supporting bar without

additional

fastening elements.

Still other objects, advantages and features of invention will

hereinafter

appear.

Referring to the accompanying drawing which 40 illustrates further

improved

embodiments of the invention over that shown in said copending

application,

Fig. 1 is a perspective view of a triple emblem bar in which one bar

has been removed. 43

Fig. 2 is a fragmentary perspective view of a parent bar from which

individual bars are cut, a portion of said bar being broken out in

order

to contract the length of the view.

Fig. 3 is a section taken on line 3—3 of Fig. 1. 50

Figs. 4, 5, are sections of modifications.

Fig. 6 is a longitudinally extending transverse section of a single

emblem bar on an increased scale showing one form of means whereby the

bar may be fastened to the garment. •*

Referring in detail to the drawing, therein is shown in Fig. 2 a

laminated

parent unit I, comprising parts 2, 3 and 4, of any desirable length

from

which the individual emblem bars of the character shown in Figs. 1, 3,

4, 5 are cut.

The plates or laminae 2 and 4 are constructed of clear transparent

plastic

material, such as cellulose acetate or Lucite, and of a size

coextensive

in area with that of the ribbon 3 interposed between them.

The manner of sealing the ribbon 3 between the plastic plates 2 and

4 to construct the unitary article I is well known in the art and the

expired

patents to Goodsell et al. 1,071,226, August 26,

1913,

and Segal 1,322,631, November 25, 1919, disclose

representative

sealing means. For the purpose of this application, various other means

may be employed to seal the ribbon in the plastic, it being merely

necessary

that the ribbon be protected by sealing or embedding the same in the

plastic

plates :to form the unitary article I having substantial rigidity.and

thickness.

After _the laminated strips 5 shown in Figs. 1, 3, 4, 5 and .6 have

been cut to the .desired length from the parent strip to form emblem

bars

of the required facial area therein shown, such strips are placed in

suitable

heated dies to form the particular beaded bar shown in Figs. 1 and 3 or

the alternate type of bars shown in Figs. 4 and 5.

Bars of the type shown in Figs. 1, 3, may be constructed of much

thinner

laminations 2 and 4 since the added strength is to be derived from

curving

the material.

In Figs. 1 and 3, the bead 6 resulting from curling in the

longitudinally

extending edges is clearly shown. These curled beads 6 provide for

yieldably

holding the emblem bar in place, when once adjusted to their proper

positions

on the mounting bar 7, and their yieldability provides for slipping the

laminated emblem bar over the mounting bar from either end or snapping

it over the edges of the supporting bar in a flatwise manner by

yieldably

spreading the beads apart sufficiently to override the beveled edges 8

or 9 of the supporting bar with which they cooperate.

Within the province of the invention as hereinafter claimed, if

found

expedient, instead of forming the curled beads 6 on the laminated bar,

this construction may be modified in conformity with the showings in

Figs.

4 and 5 where, instead of a bead the longitudinally extending edge

portions

10 are roundedly bent as shown in Fig. 4 to slidably embrace the

rectangularly

shaped supporting bar 11 or are squarely shaped, as indi

[blocks in formation]

cated by the numeral 12 in Fig. 5, to slidably embrace a similar

mounting

bar 13.

In Pig. 6 is shown, for attaching the device to the jacket of the

wearer,

an attaching element comprising the pin attaching element 14 and

securing

clip 15 for the point portion of the pin 16, ^imilar to that set forth

in said co-pending application, may be provided for attaching the

assembly

of emblem bar and mounting bar, whether it be a single, double or

triple

unit.

The steps taken in the manufacture of the device, which are in

addition

to those set forth in the already referred to co-pending application,

may

be briefly summarized as follows:

After the parent strip has been completed and rightangularly

subdivided"

into strips of the proper size for the individual emblem bars, then

their

edges where thus cut are processed by subjecting them to a buffing

operation

to remove any projecting ribbon fibers and to smooth off the plastic.

This

buffing operation is not so important;when the_ edges of the strip are

curled as shown in Fig. 3; because the curls cause the edges of the

ribbon

to be nearly concealed, but it is important in the remaining

embodiments

of the invention.

In constructing the emblem bar, after the individual sections have

been

severed from the parent strip they are put into a heated die,

constructed

to deform the bar to the shape shown in Figs. 3, 4 and 5, after which

they

are ready to be applied to the mounting bar in the manner already

stated.

This invention is intended to cover broadly any single pair or

plurality

of ribbon-protected bars utilizing a medal' decoration service ribbon

bestowed

for valor and service achieved in any campaign, whether it .be in the

Army,

Navy or any other branch of the armed or other government service.

Although

the decorative service bars are shown as being interchangeably mounted

in an end-to-end relation to each other, yet it is considered to be

within

the province of the invention, as hereinafter claimed, to apply them

detachably

to the supporting bar in any manner required to obtain this end-to-end

relation.

The emblem bars or service ribbons thus formed are sheathed in

transparent

plastic which protects them against wear and soiling in use. The sheath

thus formed is deformable as described to form on the back of each bar

a trackway created by the turned edges 6, 10 or 12. This trackway is

substantially

rigid and is mounted on the supporting bars 1, II or 13, as shown, so

the

bars may be positioned thereon without supplemental fasteners.

The portions of the formed ribbons that engage the mounting bars

have

a normal f rictional binding contact and longitudinal push-pull

slidable

contact with the engaged face, top and bottorn edges, and adjacent

portions

of the opposite face of the supporting bars which permits the formed

ribbons

to be interchangeably mounted by sliding contact yet securely held by

frictional

contact when in position.

20 What is claimed is:

The combination with an appropriately decorated normally flexible

ribbon

adapted to be. personally worn to designate a theater of military

service

or award, of a single protecting and interchangeable securing means for

the flexible ribbon comprising relatively thick plates of transparent

plastic

between which the ribbon is sealed to form a unitary article of

substantial

rigidity and thickness, a flat bar adapted to be personally worn,

against

one side of which the sealed ribbon is adapted to be mounted, and the

top

and bottom edges of the sealed ribbon being bent upon themselves in

such

a manner with respect to,the bar that the formed article has a normal

frictional

binding contact and longitudinal push-pull slidable contact with the

engaged

face, top and bottom edges, and adjacent portions of the opposite face

of the flat bar to permit the sealed ribbon to be removably positioned

on said bar and securely held by the frictional contact when in

position.

JOSEPH WOLF. 43

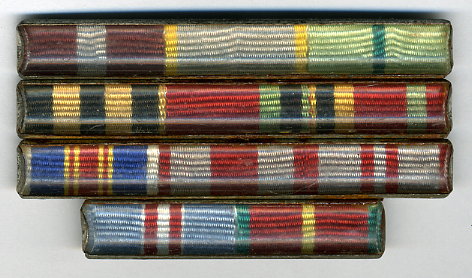

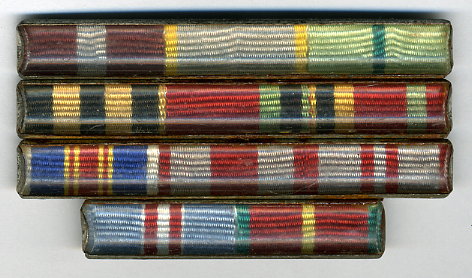

PLASTIC RIBBON PICTURES

examples of curved as in patent and earlier flat

type.

below Stamped with Wolf-Brown name, I have others with no name on them,

as CAP

CIVIL AIR PATROL

KOREAN

RUSSIAN