|

4 7amp Gecko 201A drives |

Back view of the controller. |

|

Another view. |

This is a view of the Gecko drives in the case mounted atop an aluminum heat sink. Breakout board from Camtronics |

|

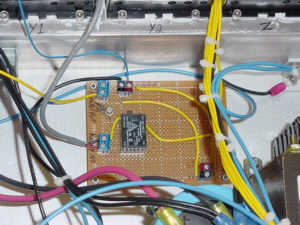

This is the relay board that I mounted in the control box to turn the plasma torch on and off by way of the parallel port. The software takes care of this. I am using SuperCam. |

View of the controller from the side. |

|

Top view of the controller. |

Another view of the controller. Here you can see the two transformers and capacitor. |

|

Close up of the transformer. |

Side view of the table. Upper frame is 3 x 4 x 3/16 tube, lower is 2 x 2 x 1/4 tube. |

|

2 inch aluminum brackets attached to the frame to support the rails. |

Angled view of the table with the aluminum rails mounted waiting on the DualVee bearing rails. |

|

Head on view of the table. |

|

|

|

My homemade CNC-PC station. I will still be using this PC for the CNC #2 table. |

salterc@frontiernet.net

salterc@frontiernet.net