unisys12 |

| Hard-core CEG'er |

|

|

| Reged: 09/08/02 |

| Posts: 3944 |

| Loc: Corinth, MS | |

CD4E FAQ CD4E FAQ

#655008 - 07/01/04 09:46 PM |

| |

I will start

off with the basic stuff, then work up to the more envolved

stuff!

--------------------

Phillip Jackson

`98 Mystique LS

262K+ and counting...

ATX rebuilt @ 151K

"This storm has broken me, my only friend!" RIP

Dime

Post Extras:    |

unisys12 |

| Hard-core CEG'er |

|

|

| Reged: 09/08/02 |

| Posts: 3944 |

| Loc: Corinth, MS | |

|

CD4E

FAQ

-----------

General Questions -

What's the

most commonly used acronyms used when talking about transmission

repair with the CD4E?

A/T - Automatic Transmission

(rear wheel drive)

ATX - Automatic Transaxle (front wheel

drive)

ATF - Automatic Transmission Fluid

MLP - Manual

Lever Position sensor (aka Range Sensor)

TSS - Turbine Speed

Sensor (aka Input Speed Sensor)

VSS - Vehicle Speed Sensor (aka

Out Speed Sensor)

Will be updated with new

information as needed and

obtained.

--------------------

Phillip Jackson

`98

Mystique LS

262K+ and counting...

ATX rebuilt @ 151K

"This storm has broken me, my only friend!" RIP

Dime

Post Extras:    |

unisys12 |

| Hard-core CEG'er |

|

|

| Reged: 09/08/02 |

| Posts: 3944 |

| Loc: Corinth, MS | |

|

Maintaince -

Why should I change my ATF on regular intervals?

A lot of people think that you should not change your

transmission fluid unless you are having problems. This is about as

wrong as you can possibly be. Look! ATF is not some miracle fluid

that will not break down. When ATF breaks down, it actually becomes

abrasive. If you allow this liquid sand paper, if you will, continue

to run through your transmission... it will eat away at everything

it comes into contact with. Keep your fluid changed on a regular

basis, all those parts will continue to be happy for a long

time.

What kind of fluid should I use, when changing

my fluid?

The CD4E is designed to use Mercon. Not Mercon

V! This holds across all models years. You can use pretty much any

brand of multi-purpose ATF fluid. You will most commonly see it on

the shelf labeled as, "DexronIII/Mercon". These multi-purpose ATF's

also cover the same specs as Type H, which the CD4E may call for in

other countrys. If you want, you can use synthetic based fluids such

as, Mobil 1 Synthetic ATF or Amsoil Synthetic ATF. There are of

course others out there and I will let you do all that research. I

will let you draw your own conclusion in that area on what is best

for your CD4E. Just stay with either Mercon or a synthetic variant

and you will be fine. And yes, if you want to slowly change over to

a syn, by performing the 4 quart drop procedure, you can.

How do I change the fluid in my CD4E?

There's

two ways. The first way is a drain and fill approach and the power

flush. There is also a manual flush that I will also cover.

A)Drain and Fill - Jack the front of the car up a small

amount. Remove the drain plug, using a 3/8" drive rachet. Allow the

4 quarts to drain out. After the ATF drains out, simply re install

the drain plug and let the car down. Add 3.5 quarts and crank the

engine. Hold the brake and work though all the gears. This ensures

that all the fluid works through the system. Leave the engine

running and check the fluid level and adjust as needed. You should

only have to possibly add the last .5 quart.

B)Power Flush -

This procedure calls for a mechanic to hook your ATX up to a machine

that will force new fluid into the ATX case and, at the sametime,

sucks out the old. The force of the fluid coming into the case

cleans out most, if not all, contaminets throughout all parts of the

ATX.

C)Manual Flush - To perform a tranny flush yourself,

follow this little "How-To" by RoadRunner, Transmission Forum

Moderator at CEG. Before you start put 4 quarts of WATER in a bucket

and mark the INSIDE of the bucket with an INDELIBLE INK MARKER, at

the top of the water level. When you get under the car, you will see

two lines that go from the transmission to the passenger side of the

car. One attaches to the BOTTOM of the radiator, while the other

goes to the TOP of the radiator. Follow the line that attaches to

the BOTTOM of the radiator back to the transmission. This is where

you want to remove the line and then put the end of it into a

bucket. Pour out the water and dry. Now you have a 4 quart measure

inside the bucket ! Start the car and let it idle while the bucket

fills. When it gets close to the 4 quart mark, turn off the car, and

pour 4 quarts of ATX Oil into the Dipstick Tube. Take the 4 quarts

in your bucket and pour it into the 4 empty ATX Oil bottles. You'll

need to repeat this until the oil coming out of the line starts to

resemble the oil you ar pouring into the dipstick tube.

I've heard that performing any type of flush can cause

more harm then good. What's the truth to this matter?

Well see here is what happens with old ATF, while still

floating around in your tranny. The old fluid flows through the

tranny, causing all sorts of damage. One of the main problems is

scaring. Scaring is where a piece of grit runs through say, the bore

of the valve body. When it reaches the piston or valve, it gets

caught between the seal and the bore. As the valve or piston

continues to work normally, it is also cutting into the bore. Now,

with scaring out of the way - As time goes by, this scare will

become filled with other particles of grit and trash. This

eventually seals whatever leaks might have been caused by the

scaring action. Now! This is just one piece of grit, so imagine

thousands if not millions upon millions of different examples of

this happening throughout an entire trip! It does not take long for

your transmission to become riddled with this damage. Well, here's

the catch. ATF is naturally very good at cleaning. And if you flush

your tranny with 12 quarts of new fluid, it is only a matter of

miles before all those scares are cleaned out and you have a

hydraulic mess on your hands. Valves and pistons will begin to stick

or leak. Line pressure will fluctuate wildly. All sorts of problems.

It is not unheard of for someone to flush their tranny, that has not

taken very good care of it, and soon after flushing - it dies.

General rule of thumb here... Take care of it, from the

beginning, and it will take care of you.

What if I bought

my used and I have no idea how the former owner took care of the

transaxle?

If you have purchased a used car, that you are

not sure about the level of care that the previous owner car gave

the transmission, I would suggest performing the 4 quart drop

routine and not flushing the tranny, right off. Wait until you have

completely at least three of the drain and fill's first. After that,

if everything is working ok, then I would suggest a flush for your

ATX.

How often should I change my ATF?

With the drain and fill method, I would suggest at least

every 10-12,000 miles. A power flush should be performed, at least,

every 20-25K. Yeah. Most transmission repairmen will tell you that

this is overkill, but... we are talking about $10-$15 here! Would

you rather pay an average of an average of $20-$50 a year (given

that you drive an average of 30K a year) or $2500 over a week, while

your CD4E is rebuilt by some guy at a shop that you don't know

rebuilds something that you have no idea about?

How

do I change the filter in my CD4E?

The filter, in the

CD4E, is not a serviceable item. By this, I mean that the filter

cannot be changed without actually disassembling the transmission.

Don't go and get all upset about this! The filter actually works

pretty good. The only known problem with the filter, was found back

in `98, I believe. It was redesigned by Flitrek to address a fluid

flow issue during extreme useage. In other words, when you would

drive your car like a mad man - like most of us do on weekends, the

fluid was not able to flow properly through the filter. This lead to

premature failures of the coast & direct clutches. But if you

are running alot of horsepower or torque, then might I suggest a B&M External Filter.

--------------------

Phillip Jackson

`98

Mystique LS

262K+ and counting...

ATX rebuilt @ 151K

"This storm has broken me, my only friend!" RIP

Dime

Edited by unisys12 (08/04/04

10:17 PM)

Post Extras:    |

unisys12 |

| Hard-core CEG'er |

|

|

| Reged: 09/08/02 |

| Posts: 3944 |

| Loc: Corinth, MS | |

|

CD4E FAQ

----------

Modifications -

Modifications to the

CD4E are few and far in-between. Actually, modifying the CD4E

actually means building it up for better reliability. The weakest

point of the later model CD4E's found in the Contours is the torque

convertor bypass valve, located in the Valve Body. This valve was

poorly designed, but thankfully, Sonnax makes a replacement valve

that solves this issue. Actually, there are several weakpoints, as

with anything made by man, and the fact that there are several weak

points that can be addressed and when addressed properly, can

increase the overall reliability of the transaxle.

So what

about performance modifications? Well, there aren't any. The only

real performance mods you can do to the CD4E is take the Direct and

Coast clutch packs from the 98-2000 models, which host High-Energy

Kevlar Composite clutch plates, and the 2000 model CD4E found in the

Escape and Tribute also have a wider High-Energy band. Thes small

changes will help with overall clutch life, which takes us right

back to the fact that modifying the CD4E means modifying for

reliability and not so much for performance. Since I first typed

this, almost a year or so ago, Level 10 has released the PTS

clutch packs that they use when rebuilding their

high-performance CD4E's. I have many thoughts here, but since this

is a FAQ, I will leave it at that.

Below I will list of a

few of the more common modifications that can be made to this

transaxle along with how-to's were I can.

External

Cooler

An external cooler is a wise investment for any

automatic transmission, no matter what type! The number one killer

of any automatic transmission is heat. By adding an external cooler

will greatly decrease the overall operating temperature of the unit.

This will help in several areas like; fluid & clutch life and

operation.

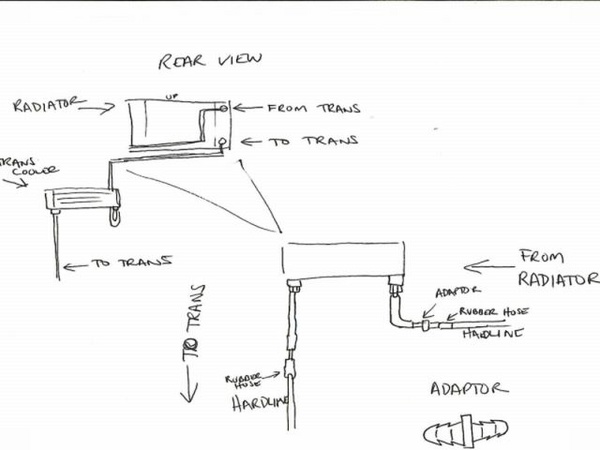

So how can I install a cooler on my car? Well

here is a quick drawing that Hector (LoCoZ2.0 is his screen name of

the CEG forums) did for someone awhile back.

As you can

basically see, all you have to do is tap into the "return line"

coming from the radiator to the trans and place the cooler there.

Mounting the cool is really based on where you have room to mount

it. Just make sure that it gets plenty of air flow. Most place it in

front of the A/C Condenser. Most of the people that have installed

these have noted that mounting it here does not affect the overall

performance of your A/C.

This is actually a simple

operation, that most anyone could do themselves over a weekend. It

can also be done, most of the time depending on the brand and size

of cooler you use, for less then $100! Most only spend about $70 for

all the parts including all fittings. Not bad for something that

could easily save you several thousand dollars for a rebuilt

tranny!!

Full Synthetic ATF

"Not only have

we not had a single member lose a CD4E while using it, if they

started using it early enough, but the temperatures that these guys

run are just sick! One member has claims of, in the winter, 90

degree operating temperatures while driving on the highway when the

outside temps are 50 or below. City driving, under the same

conditions were around the 110 - 150 degree range. When the temps

are well above 50, normal operating temps were around 120 - 150

highway and city is around 175 - 200. The normal operating temp of

the CD4E is around the 220 degree range. Bear in mind that these

numbers come from the combined use of the full synthetic ATF and an

external cooler. AWSOME!!"

I will say again, do your own

research here. I cannot possibly cover every fluid manufactuer out

there and give you a straight answer. Do your homework and pick what

you feel the most confident with.

Shift Kits

"Plain and simple... There aren't any performance kits

available! The only thing on the market right now that has anything

to do with shifting for the CD4E is the TransGo CD4Ejr kit. This is

more of a problem solving kit that, when installed, fixes a bunch of

known weak points of the CD4E's hydraulic system. Most of the kit is

for the valve body. The valve body can be removed easily enough and

the kit includes all the needed bits for drilling out the valve body

where needed. Here's a link to the TransGo site, which you will

be able to better educate yourself on it's purpose. If you would

like to purchuse one of these kits, you can check Bulkpart.com. There's also a nice thread, located

here that contains a link to the instructions that

come with the CD4Ejr kit. That should help give you a head start on

what to look for in this project."

High Energy Clutch

Packs

"If the build date of your CD4E is pre96, you can

have High Energy clutch packs installed. In 1996, the coast clutch

replaced with the High Energy material and in `97 the Direct clutch

was as well. These packs are only available, for the Direct &

Coast clutches. High Energy clutches are clutches made with a Kevlar

Composite material. Raybestoes and Borg-Wagner both make aftermarket

High Energy clutches for the CD4E."

Now for

some random possibilities that I bet a lot of people will laugh at,

but it's just stuff that I have thought about. (uh oh! There I go

thinking again!!)

Swapping Around

"Alright! So 3L swaps are all

the rage right now with the Contour and Cougar. So what if someone

did all the normal engine swapping, but instead of using a normal

CD4E, use one out of the Mazda Tribute. Well, you would not have to

find just a Tribute I don't think, but any 2001 or above CD4E would

possibly work. Anyway, my point here is that the Tribute has a

little more aggressive shift pattern that is better suited for

street use. You could then get a chip from Streetflight or someone

like that, which would accentuate that aggressive shifting even

more. Why not? Hey it is just an idea?"

Cooling

Issues

"We all know that the CD4E has some serious

cooling issue's. So how might we be able to cool the tranny even

better then the above mentioned method of stuffing a small unit in

front of all the other stuff that is down there already (power

steering cooler, a/c condenser and radiator). What if you took a

radiator from an SVT contour, which has a little better flow

characteristics then no-SVT radiator, and replace the stock one with

this. Then remove the a/c condenser, which would make more room for

a larger tranny cooler. This action would also remove the CD4Es

cooling system from the radiator, which would be a good thing. Even

if you had an external cooler installed and your engine overheated,

you could still run the risk of causing the ATF to become super

heated if the conditions were right. If you didn't want to go with a

Contour SVTs radiator, you could get a Focus radiator from Fluidyne.

I am not sure if it would be an exact fit, but something to think

about anyway and that is what all this is about."

How-To's -

CD4E Trans Temp Gauge Install

How-To

"Go to Summit Racing and get yourself a 5/16" Autometer

Trans Temp Manifold.

You can install this like I did, but

you've got to be extremely careful in your measurements, cause this

will come really close to your lower radiator hose. I installed my

temp sensor so that I could read the ATF oil temperature after it

leaves the tranny, but before it enters the radiator cooler. This

temp reading coincides with the same reading you will get using a

scan tool and looking up the TFT value. (Transmission Fluid

Temperature)

Only cut the ATX oil cooling line using a pipe

cutter. Do NOT use a hacksaw or a jig saw. You will introduce metal

shavings inside the pipe, or you will bend the pipe out of round.

Follow the ATX Cooler line from the top of the rRadiator

back to the transmission. Crack the fitting at the radiator and

remove the line. Crack the fitting at the transmission and remove

the line from the vehicle.

Following the directions that

come with the manifold, you want to leave about 1/2" - 1" of pipe

between where you cut the pipe, and the elbow behind the nipple that

fits into the radiator cooler. Mark where you are going to make your

upper cut into the pipe, mark where you are going to make your lower

cut into the pipe based on the manifold's directions. Fit the temp

sensor into the manifold using teflon tape to seal the threads. Fit

the couplings into the manifold using teflon tape.

Now using

a bolt and nut that will fit all the way through one of the mounting

holes on the manifold. You want to anchor about a 3' section of wire

using a terminal that fits over the head of the bolt. This is going

to become your ground strap for the sensor. Since the ATX Cooler

Lines are not all pipe, the portion of the pipe that attaches to the

radiator is isolated from the vehicle and not grounded.

Attach the compression fittings to the cooler lines and

assemble the lines to the manifold. Make sure that you position the

pipes as close to their original positions as possible. They don't

have to be exact, you can alwasy bend the pipes a little to get them

into the correct position.

Attach one end of the wire you

are running from the sensor to the gauge, at the sensor, also using

a terminal that fits over the bolt.

Reinstall the cooling

line. (When I reinstalled my line, a corner of the manifold was

pressing against my lower radiator hose. I had to remove the cooler

line and use a Dremel to cut enough material off the corner of the

manifold block so that it would not touch the lower hose.)

Attach the sensor wire to the gauge.

Cut accordingly

and attach the ground strap to a ground point on the radiator

support just behind the headlamps. You will see about two or three

black wires that are all attached to the support, just behind the

passenger headlamp, on the engine compartment side of the radiator

support. I used this point to anchor the ground strap.

That's it! Check the oil level of your transmission. You

will lose some oil when you remove the line, but it shouldn't be

more than 1/2 quart.

- Pete (Roadrunner) The offical

CEG CD4E Burner!!

CD4E External Cooler

Install

This way will save you from having to cut any of

your stock lines incase you are on a lease.

Parts List:

-Tranny Cooler From a post by Terry Haines: Terry suggested

either a Hayden 'Ultra-Cool' (#404 side connections) or a

'Rapid-Cool' (#678 bottom connections)

-About 6 feet of 3/8 inch

transmission hose. (Get longer if you're not sure or your cooler has

a bottom feed)

-2 hose barbs/adapters One male, one female

-4 hose clamps

-Teflon tape, or your sealant of choice

-Brackets

-Sheet metal screws

-Zip tie style holders to

hold the cooler (will probably come with the cooler, otherwise the

guy at the parts shop will know what you need)

-Zip ties

-Fresh tranny fluid

Tools needed:

-3/4 inch wrench

-3/8 inch ratchet

-Short ratchet extension

-8mm socket

-Scissors or utility knife

*Obligatory Disclaimer: I'm

not responsible if you ingest tranny fluid, it tastes nasty, but

you'll live, maybe, probably not. Tranny fluid does seem to make

good hair conditioner though. Also don't be dumb, and drop your car

on yourself. I'm not going to hold your hand through this install,

you'll have to figure out some for yourselves, but please ask

questions in the forum if you have any)*

Step 1)

Park on a flat surface, secure your car from rolling (don't be lazy

and just set the parking break, chock those back wheels) jack it up,

and put jack stands under it.

Step 2) Drain the oil from the

transmission through the drain plug. This will keep all the fluid

from pouring out of the cooler hoses and help with that fluid

ingestion part. Just use the square end of a 3/8 inch ratchet and

short extension, no sockets needed on this one.

Step 3) You

will probably need to remove some shield right now to access the

space behind the bumper. Matt and I didn't need to do this because

his 2000 didn't come with it. (matt, put a smiley here)

Step

4) Crack open a beer with your buddy.

Step 5) Place a pin in

the tab in the top of the radiator. (not necessary, we did the

install without it, but it's in the Ford manual so it's probably a

good idea) This is to keep the radiator from falling down when you

remove the bottom support.

Step 6) Remove the two 8mm bolts

that hold the lower radiator mount in place, and turn it around so

you can access the lower hose connector of the radiator.

Step 7) Undo the flare nut (3/4 inch) that holds the lower

tranny cooler return line in the radiator. Be prepared with a bucket

for the fluid that will pour out.

Step 8) Time for another

beer!

Step 9) Take your two hose adapters, using teflon tape

or your sealant of choice, put the adapters onto the tranny hose and

into the radiator. Make sure to use sealant, otherwise it will leak

and you'll have to do this all again (voice of experience here)

Step 10) Test fit your cooler, and cut the hose to length.

We routed them along the same path as the power steering cooler

lines. You may place it wherever you wish, we put it in front of the

AC condenser but not against it. You don't want to put the cooler

against the condensor or ps cooler, because then you will be heating

the tranny cooler and it wont do it's job as effectivly.

Step 11) The brackets we used were from a B&M cooler

kit, but you can find something similar at a hardware store. The

tops were bent over so that we could use sheet metal screws to

attach them to the metal behind the bumper.

Step 12) Grab

another beer and admire your handy work on those brackets

Step 13) Attach your hoses to the cooler and to the hose

adapters and clamp them in place. You might want to orient the hose

clamps so that you can undo them later with out removing the cooler.

You might need to pop the hard metal line for the tranny out of it's

holder and slide it sideways so the hose adapters can clear each

other and fit like stock.

Step 14) Attach the cooler to the

brackets, we used the black zip cord things that came with the

cooler, and used the foam pads to cushion the fins of the cooler.

Step 15) Secure the hoses in place, we used zip ties.

Step 16) Put the radiator mount back in place with the two

bolts.

Step 17) If you haven't already, put the drain plug

back in place, using some teflon tape to seal it up.

Step

18) Get your funnel out and replace the fluid you took out with 5

quarts of new fluid. (maybe a little more to make up for the fluid

that will be in the new cooler and hoses) If you run the engine

while doing this, the fluid will be circulated through the

transmission and cooler lines and not spill out of any vent holes.

This is a problem when refilling transmissions that are completely

drained and might not apply here, but it couldn't hurt. If you're

feeling ambitious (read drunk) you could replace all your fluid with

the hoses attached to the adapters and not the cooler.

Step

19) Take those jack stands out from under there, and drop, I mean

lower(!) the car back down. (not the voice of experience here, but I

like seeing the look on Matt's face when I suggest something like

this around his car.

Step 20) You guessed it, one more beer.

Unless you're going to go test drive the car, in that case skip all

the beers and have your sweetie make you some kool-aid.

Notes: This install went fairly easy for us, and looks very

clean. Its hard to tell that anything was done even from underneath

except for the bright shinny cooler. A black one would probably be

completely stealth. We only had a few problems. We ran into some

trouble when we were getting the new hoses onto the cooler, they

were a very tight fit. We tried heat, grease and stretching out the

hose with a larger bolt. In the end it just took time to get it on.

We also had some trouble getting to the flare nut on the radiator

until we moved the mount out of the way. We also put the cooler

inline after the stock one in the radiator. This will let the

radiator pull a lot of heat out of the fluid and let the new one do

the rest, as opposed to taking the heat out of the fluid and then

putting it back in when it flows through the radiator. This will

also help in the winter in that the fliud will be warmed up faster

in the radiator to get the tranny up to operating temp. All in all

this is an easy job that just about anyone could do, you just need a

little know how and a few simple tools. If you need help enlist a

friend, that's how I keep ending up working on Matt's car.

-

Chlorine & SpeedDemon (Dan & Matt)

A few things

I might add here... Another cooler that quiet a few people have used

is the B&M Super Cooler. This cooler comes in a kit that

includes all the necessary fittings and tubing that might be needed.

Bear mind that the Contour does have a slightly different size

fitting then most. IIRC, it is 5/16, so you might have to get the

fittings from somewhere else.

- unisys12

I

would also like to add here, that if anyone has anything that they

would like to add or any questions about this FAQ, please either

start a thread here about it or PM me. I am always looking to expand

on any information that I may have and I am not too proud to make

corrections.

--------------------

Phillip Jackson

`98

Mystique LS

262K+ and counting...

ATX rebuilt @ 151K

"This storm has broken me, my only friend!" RIP

Dime

Edited by unisys12 (08/22/04

08:18 PM)

Post Extras:    |

unisys12 |

| Hard-core CEG'er |

|

|

| Reged: 09/08/02 |

| Posts: 3944 |

| Loc: Corinth, MS | |

|

CD4E FAQ

----------

CD4E OBD-II Information -

TRANSMISSION INPUTS

The Analog Transmission

Range (TR) sensor provides a single analog input to the PCM. The

voltage corresponds

to the driver-selected gear position (Park,

Rev, Neutral, OD, 2, 1). This input is checked for opens and shorts.

(P0707, P0708)

The Turbine Shaft Speed (TSS) sensor and

Output Shaft Speed (OSS) sensors are analog inputs that are

checked for rationality. If the engine rpm is above the torque

converter stall speed and engine load is high, it can be

inferred that the vehicle must be moving. If there is

insufficient output from the TSS sensor, a malfunction is

indicated (P0715). If there is insufficient output from the OSS

sensor, a malfunction is indicated (P0720).

TRANSMISSION

OUTPUTS

Shift Solenoids

The Shift Solenoid

(SSA and SSB) output circuits are checked for opens and shorts by

the PCM by monitoring the

status of a feedback circuit from the

output driver (P0750 SSA, P0755 SSB).

All vehicle applications

will utilize an inductive signature circuit to monitor the shift

solenoids functionally. The ISIG

circuit monitors the current

signature of the shift solenoid as the solenoid is commanded on. A

solenoid that

functions properly will show a characteristic

decrease in current as the solenoid starts to move. If the solenoid

is

malfunctioning, the current will not change (P1714 SSA, P1715

SSB). The ISIG test runs in conjunction with the

other

transmission functional tests. The lack of communication between the

ISIG chip and the PCM

microprocessor is also monitored (P1636).

Torque Converter Clutch

The Torque Converter

Clutch (TCC) output circuit is a duty-cycled output that is checked

electrically for opens and

shorts by the PCM by monitoring the

status of a feedback circuit from the output driver (P0743).

The

PWM used to control CD4E's TCC does not have sufficient inductive

signature, therefore on these

applications the TCC solenoid is

functionally tested by monitoring converter slip. If the TCC is

failed on when

commanded off, a P1742 fault code will be stored.

If the TCC is failed off when commanded on, a P0741 fault code

will be stored.

Electronic Pressure Control

The EPC solenoid is a variable force solenoid that controls line

pressure in the transmission. The EPC solenoid

has a feedback

circuit in the PCM that monitors EPC current. If the current

indicates a short to ground (low

pressure), engine torque may be

reduced to prevent damage to the transmission. (P0962, PCA)

TFT - Transmission Fluid Temperature sensor. Used byt

the PCM to determines shift point characteristics based on the oil

temperature of the transaxle.

From the `98 Ford Service

CD -

"The MIL is illuminated for all emissions related

electrical component malfunctions. For malfunctions attributable to

a mechanical component (such as a clutch, gear, band, valve, etc.),

some transmissions are capable of not commanding the mechanically

failed component and providing the remaining maximum functionality

(functionality is reassessed on each power up)- in such case a

non-MIL Diagnostic Trouble Code (DTC) will be stored and, if so

equipped, a Transmission Control Indicator Light (TCIL) will flash."

What this basically means, is that the CEL will illuminate,

and stay that way, during an emmissions related electrical component

faliure or malfunction. That is until the PCM memory is either

cleared manually or the fault is not detected after two consecutive

drive cycles.

If there is a mechanical failure, in the

tranny, it will cause the TCIL (O/D light) to flash, which means

that the PCM has stored a code indicating which fault it was. But!!

This code will be cleared once the engine is turned off.

So.

If your O/D light flashed, there was a code there to be read. If you

turned your engine off before you could actually read that code,

that code would disappear. If when you started your car again and

the CEL was not on or the O/D light did not flash, there is nothing

there to read. You will have to wait until the fault happens again.

--------------------

Phillip Jackson

`98 Mystique LS

262K+ and counting...

ATX rebuilt @ 151K

"This

storm has broken me, my only friend!" RIP Dime

Edited by unisys12 (07/26/04 09:27

PM)

Post Extras:    |

unisys12 |

| Hard-core CEG'er |

|

|

| Reged: 09/08/02 |

| Posts: 3944 |

| Loc: Corinth, MS | |

|

CD4E

FAQ

----------

CD4E Differences -

Clutch

Plates

94-95 Friction - Direct

96-Up Friction - Direct /

High Energy material

94-96 Coast Clutch

97-Up Coast Clutch /

High Energy material

94 Steel - Direct - .078 - 3/4(qty)

95-96

Steel - Direct - .118 - 3(qty)

Pressure

Plates

94-97 Coast

98-Up Coast (redesigned)

94-98 w/o

Forward Wave Plate

98-Up w/ Forward Wave

Plate

Hard Parts

94 Pump Gears - .567

thick

94-Up Pump Gears - .603 thick

94-96 Pump Wear Plate 1st

design

97-Up Pump Wear Plate 2nd design (will retro

back)

94-98 Input Sprag - Wide Sprag (up to 1/98)

98-Up

Input Sprag - Narrow Sprag (from 1/98)

Drive Chain:

94-Up

2.0L Ford Contour - 3/4" Wide - 45 Links - E.T. Guides - 55T

Drive/50T Driven

94-99 2.5L Ford Contour - 1" Wide - 46 Links -

E.T. Guides - 55T Drive/54T Driven

00-Up 2.5L Ford Contour -

3/4" Wide - 46 Links - E.T. Guides - 55T Drive/54T Driven

94-Up

2.0L Mazda/Probe - 3/4" Wide - 46 Links - E.T. Guides - 55T

Drive/54T Driven

94-96 2-4 Servo Piston (1st

design)

97-98 2-4 Servo Piston (2nd design) 4mm Shorter

94-96

Servo Spring (1st Design)

97-98 Servo Spring (2nd Design) Green

in color

94-98 Coast Clutch Piston (1st Design)

98-Up

Coast Clutch Piston (2nd Design)

94-98 Drum -

Forward/Direct

98-Up Drum - Forward/Direct w/Forward Wave

Plate

94-98 Spring - Forward - Piston Return - 1st Design -

(to 1/98)

98-Up Spring - Forward - Piston Return - 2nd Design -

(1/98-Up)

94-98 Piston - Forward - 1st Design - (to 1/98)

98-Up Piston - Forward - 2nd Design - (1/98-Up)

94-96

Valve Body - Various Models

97-Up Valve Body - Various Models

94-Up 55T/50T - .625 Wide - 26T Sun Gear - 2.0L

Contour

94-Up 55T/54T - .625 Wide - 26T Sun Gear - Probe, 2.5L

Contour 00-Up

94-99 55T/54T - .855 Wide - 26T Sun Gear - 2.5L

Contour

Electrical Components

94-97

Sensor - Input (Pump) Beige w/green connector

(Probe/Mazda)*

94-Up Sensor - Input (Pump) Beige w/black

connector (except Probe/Mazda 94-97)*

94-Up Solenoid Block

Assembly - High Resistance (this will retro back, but older low

resistance will not)

*The Input sensor (aka turbine speed

senosr) current part number is 1S7Z7M101KA. This covers all models

of the CD4E.

--------------------

Phillip Jackson

`98 Mystique LS

262K+ and counting...

ATX rebuilt @ 151K

"This storm has broken me, my only friend!" RIP

Dime

Post Extras:    |

unisys12 |

| Hard-core CEG'er |

|

|

| Reged: 09/08/02 |

| Posts: 3944 |

| Loc: Corinth, MS | |

|

CD4E Links FAQ

--------------

CD4E Related Links and Iformation -

Company Produts -

Sonnax

www.transmissionspecialty.com/TB/TB-Volume02-01.pdf

- Has a host of information about the CD4E and products to fix

several things.

http://www.transmissionspecialty.com/TB/TB-Volume-09.pdf

- Drum overheating due to worn valve body wear or sticking pistons.

http://www.transmissionspecialty.com/parts/DM/CD4E.htm

- A whole list of parts kits Sonnax has to eliminate known problems

with the CD4E.

SPX Filtran

http://www.spxfiltran.com/bulletins/toledo/techbulletin.asp?num=046

- Coast Forward Clutch Piston

http://www.spxfiltran.com/bulletins/toledo/techbulletin.asp?num=047

- Early Pump Plate Gasket disclaimer

http://www.spxfiltran.com/bulletins/toledo/techbulletin.asp?num=048

- Revised CD4E Pump to Stator Plate

http://www.spxfiltran.com/bulletins/toledo/techbulletin.asp?num=049

- Pump Body Seperator Plate Warning

CD4E Related Websites

-

http://www.dustbury.com/626/trans.html - The first

site I found on the internet with good information that was easy to

read and understand. Very good information here.

The A-Team -

Site related to the Ford Probe, but they have a lot of good info on

the CD4E as well.

Probe/626/MX6 FAQ - Lots of really good

information about cooling products here!

CD4E Shopping Experience - This is a thread that

contains a lot of research that I did after my CD4E died. This is

thread has lots of links and information in it as well.

How-To's -

http://www.fastcougar.com/forums/messageview.cfm?catid=14&threadid=70919

- Fastcougar's How-To on changing the TSS, with part number and

pics.

ATX Rebuild Picture Story - btartman's rebuild

pictorial of his `95 CD4E. Lots of great info all thoughout!

--------------------

Phillip Jackson

`98 Mystique LS

262K+ and counting...

ATX rebuilt @ 151K

"This

storm has broken me, my only friend!" RIP Dime

Edited by unisys12 (03/27/05 07:53

AM)

Post Extras:    |

unisys12 |

| Hard-core CEG'er |

|

|

| Reged: 09/08/02 |

| Posts: 3944 |

| Loc: Corinth, MS | |

|

VSS

(Vehicle Speed Sensor)

I had to change my VSS late this

afternoon, so I thought I would walk you guys through the process on

my Duratec/CD4E. It's really not all that bad, except unplugging the

connector. My symptoms were pretty simple... Bouncing/in-accurate

seedo and once that was bad enough, the tranny would not shift

properly.

- Secure the vehicle, in the air, safely.

- Remove your air

cleaner & tubing.

- Reach down, under the brake booster,

and locate the VSS connector. You can actually see it better from

the bottom, just no way to actually reach it from there. It will

take some serious single handed twisting to disconnect this

connection, but don't give up!

- From under the car, use a

5/16" wrench to remove the single bolt from the VSS retainer. * Note

that this retainer looks like it is upside down, with a tab resting

on the case of the tranny. Don't fret! This is normal, but be sure

to replace the retainer in the same way that it was

removed.

- Grasp the sensor body and lightly wiggle it out of

it's location. Use gently force when wiggling, but apply steady

pressure upwards. The sensor body should slide right out. Do not

jerk upwards on the sensor, when removing it, or you will run the

risk of gear coming off the end of the sensor. This is not a real

big deal, since the gear itself is about an inch tall. Along with

the added shaft that is part of the gear, the gear assy is probably

around 4 inches long. You should be able to grasp it with a pair of

crooked needle nose pliers, but it would be one hella tight

fit!!

- Once the sensor is out of the case and you have

removed the gear assy from the sensor body, use a rag to wrap around

the body of the sensor base. This part of the sensor is metal, so we

don't want to damage it. Use a pair of pliers and grasp the metal

part of the sensor. LIGHTLY! Do Not Squeeze Hard!! Just apply a

small amount of pressure here. And use a 1" wrench on the plastic

part of the body and seperate the two halfs.

- At this point,

you get simply reverse. But something that I should note here...

There is a seal on the metal half of the sensor base. Be sure to

inspect this seal closely or better yet, just replace it. Also, be

sure to clean everything really good and lube everything down with

CLEAN ATF before putting it all back together.

Part number of

the sensor - F-F5RZ-9E371-BC

Cost of part - 44.67 + tax =

47.80

Part was purchused from local Ford Dealer

Reason

for sensor replacement - Notice about a week ago that when traveling

over bumpy roads, that my speedometer would fluctuate +/- 5mph.

Monday, of this week, it progressivly got worse (of course) and the

speedo would actually stay at 0 when taking off from a stand still,

as well as droping to 0 when I let off the gas. In only 60 miles of

driving, on that day, it managed to toast the ATF I had in there,

which only had about 5K on it. Yes, I have also changed my ATF as

well.

Results -

by Phillip

(unisys12)

------------------------------------------------------------

--------------------

Phillip Jackson

`98 Mystique LS

262K+ and counting...

ATX rebuilt @ 151K

"This

storm has broken me, my only friend!" RIP Dime

Post Extras:    |

|