Magnavox NA383 Digital Convertor Box

Remote

Device description

by David DiPaola

Background:

Due

to the limited usable space in the radio frequency spectrum, the government has

recently mandated that broadcast television be switched from the archaic NTSC analog

standard to the new digital standard. The switch was made so that a large block

of frequencies previously allocated to terrestrial television broadcasts could

be sold to private companies to further aid the development of nationwide

wireless networks. But, there is a problem: millions of people in the U.S. rely

on analog broadcasts on their analog television sets. This is where our

convertor box comes in. It allows old analog televisions to receive the new

digital broadcasts over the air using their existing television and antenna

system. In order to control this box conveniently, we’ve added an infra-red

remote control to our system, allowing customers to operate the box from a

distance of up to 20 feet.

Definition and

Functionality:

An

infra-red remote (commonly abbreviated to “remote” or “clicker”) is a device

that reads button presses and serializes them over an infra-red beam, which is

received by the unit it controls and the unit acts accordingly.

General

Description:

The

remote is about 5 inches long, 2 ½ inches wide and at its thickest

¾ of an inch thick. We’ve decided to use black plastic for the case in

order to give the remote a similar appearance to other remotes that would be

commonly found in this environment. The buttons are rubberized in order to

provide reliability and a good tactile response, as well as minimize cost and

complexity. Some of the key buttons, such as the channel up/down and the power

buttons are colored in order

to differentiate them for further ease of use.

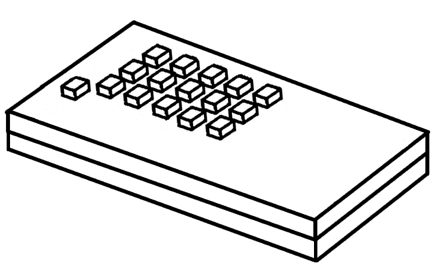

Figure 1: A view of the

whole remote

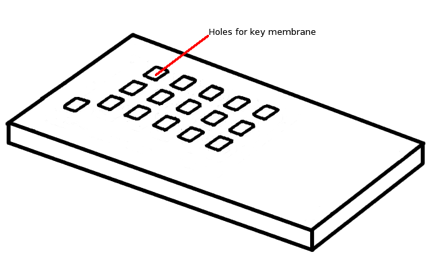

Figure 2: A view of the

top half of the plastic shell

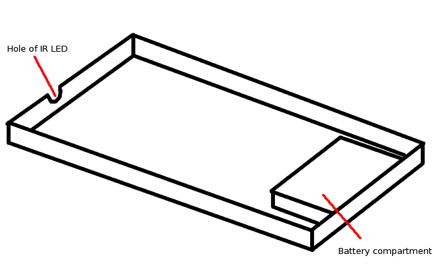

Figure 3: The bottom

half of the plastic shell

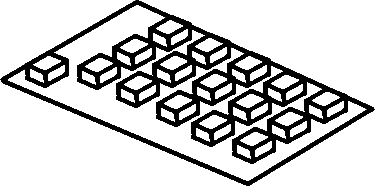

Figure 4: The key

membrane

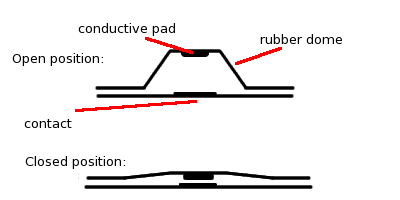

Figure 5: A description

of the key mechanism

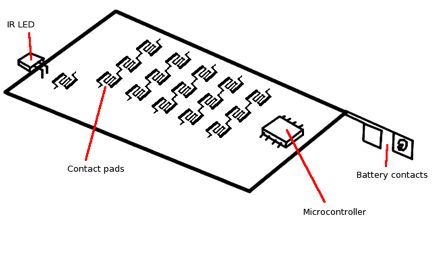

Figure 6: The printed

circuit board

Part Listing:

-Plastic

shell

-Holds

components in an ergonomic case

-Black

in color, made of lightly textured plastic

-About

5 inches by 2 ½ inches by ¾ of an inch

-Weighs

about 7 grams

-Manufactured

using injection molding

-Membrane

-Contains

conductive pads which allow button presses to be made

-Black

color, with blue channel buttons and a red power button

-About

4 inches by 2 inches by ½ of an inch

-Weighs

about 3 grams

-Manufactured

by injection molding

-Printed

Circuit Board

-Contains

all button contacts and electronic components

-Greenish in color, contact pads are black. Made

of copper on a

fiberglass

base with a layer of non-conductive insulation over the top

-

About 4 inches by 2 inches by ½ of an inch

-Weights

about 5 grams

-Manufactured

at remote location, using wave soldering to secure

electronic components

Assembly:

Laying

down the bottom of the case, with the open cavity facing upwards, lay the PCB

down so that it fits into the lower half of the case. Then lay the membrane

over the appropriate parts of the printed circuit board. Then lay the top half

of the case so that is fits snugly with the bottom half. Screw together all

three screws on the backside and snap in the battery cover.

Explanation of Function:

When

the user presses a button, a connection is bridged, which sends a small amount

of electricity to the microcontroller. The microcontroller then pulses the

infra-red LED with information that corresponds to the button’s function. The

infra-red beam is received by the converter box, and the appropriate action is

executed.