The Electric Table (Ver. 1.0)

I've

only seen a

couple of dinette table mount systems: The wall

hung,

swing bracket type and the two-post type. Both are

non-adjustable

in height, require physically lifting the table, and are either all the

way up up or all the way down. And

"up" is just too high for comfortable use of a laptop.

(I

never have gotten use to using a laptop on my lap.) , or, as we've

found with the current arrangement, too high for normal use.

Some

time ago, I made a

different kind of "manual" bracket that allowed intermediate height

positions but it still

required someone to physically lift the table. This is

difficult for the Mrs. There had to be a better

way...

The

following solution

seemed pretty frivolous at first but after thinking it over,

something invoving a motor seemed possible. That decided, I started

putting

the following prototype together.

Click

on picture for larger image.

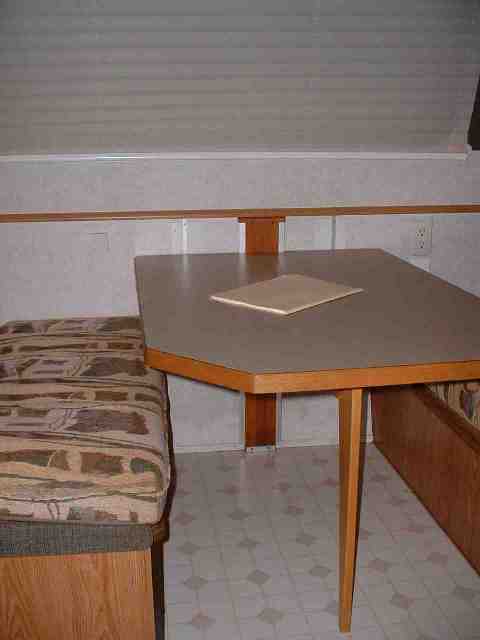

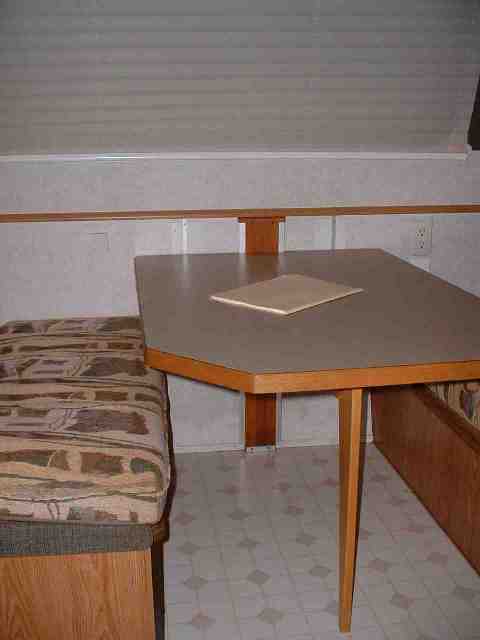

Here's

what the Electric Table looks like from a normal perspective.

To change the

height, operate a small toggle switch just under the front edge of the

table.

More on the

leg, below. |

|

|

This

is the over all view of the hardware without the table. The

black

arm is a diagonal support made from 1/2" conduit that provides cantilever

support

when moving the table up

or down.

The table

top is screwed to the "T" bar in the back and connects to the conduit

near the

middle. See below for a better picture.

The cable dangling near the bottom ends

in a double-pole, double-throw,

center-off switch that reverses the motor for "up"/"down".

This switch is mounted under

the front edge of the table |

|

|

A view of

the right

side of the motor, a 24vdc worm-drive windshield wiper unit that

has plenty

of

power at 12 vdc to lift the table. Got it from a surplus

outfit

on-line. All the other stuff, unless otherwise stated,

is out of the hardware store or my junk box.

From

down in bed postition to maximum height takes 10 seconds. |

|

| Left

side:

100 lb test aircraft cable winds on a drum that is

set-screwed to

the motor shaft. The cable goes down, around the sheave near

the

bottom and up the back where it's secured to the rear rail support.

The motor thus travels with the table. The red and

black

switch is the down limit and is rigged to sense the cable tension.

If the cable slackens, either because the table is

down all

the way or hits an obstruction (like someones lap or a

cushion)

the cable relaxes, the follower releases the switch and the down

circuit is interrrupted. |

|

| A

closeup of the down limit switch. The white rollers reduce

wear

on the cable. The brass arm bends at 90 deg and pivots at the

bottom. The upper roller contacts the cable. It's

easier to

see how tension of the

cable keeps the switch closed until something obstructs the downward

table movement. Not shown is an auxillary spring that keeps

more

tension against the cable than provided by the switch. This

keeps

the cable from looping off the drum. |

|

The

up limit

switch. I forgot to take a picture of this prior to

installing the assembly but it's just a

Radio-Shack micro-switch with a small roller arm. The roller

rides on the edge of the left rail and drops into a shallow dip where I

wanted it to stop.

Shown here is one of four slotted polypropylene blocks that slide on

the aluminum angle iron rails. I chose this mostly to avoid

having to mount a dozen rollers to restrict the carriage to

only

up-down motion. (It was

a prototype, afer all...) As it turned out, the blocks work

fine |

|

| Here's

one of the two "wiggle stops" that help laterally stabilize the table.

They press lightly on two aluminum strips that are screwed to the

wall. |

|

| A

view from beneath with the table installed. The two legs

folded

up are left over from the previous manually adjusted model.

Even

though the table is quite sturdy and works fine in cantilever mode,

I've decided to keep one of the legs in place and drop it down

when the table is being used

in the up position just to protect things from someone leaning or

sitting on

the table. The machinery is strong but the wall paneling is

not.

(See comment, below). |

|

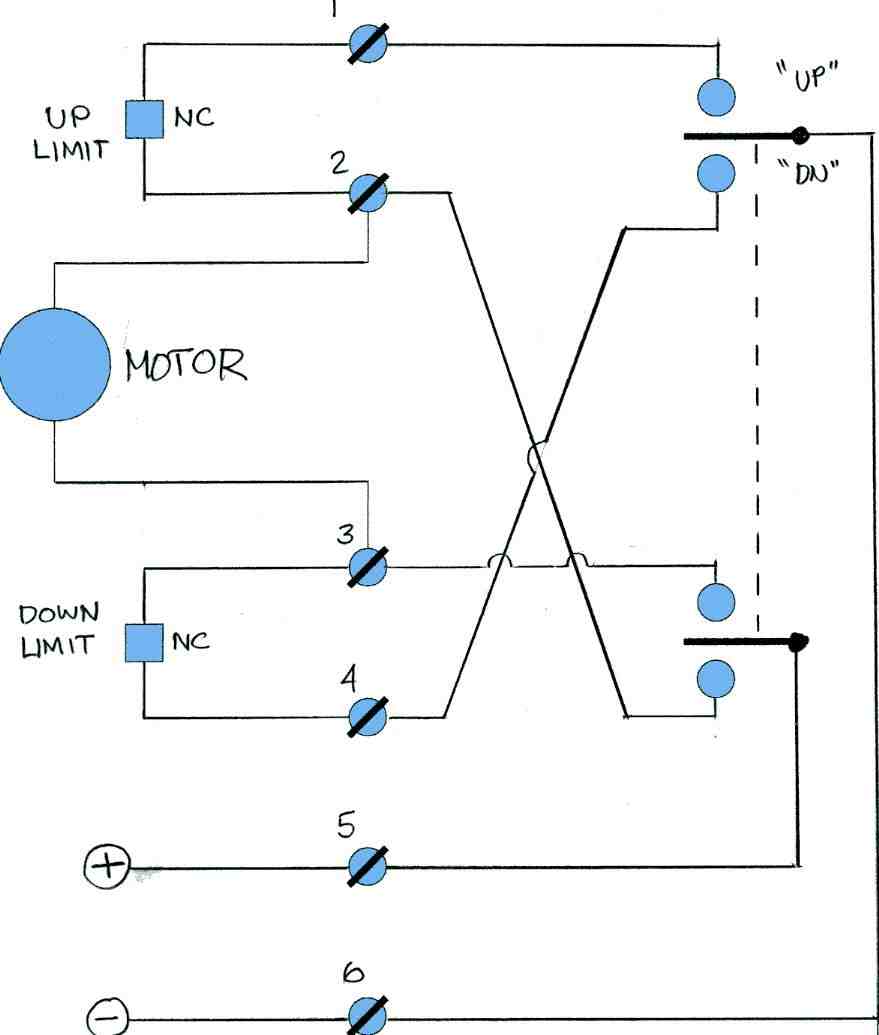

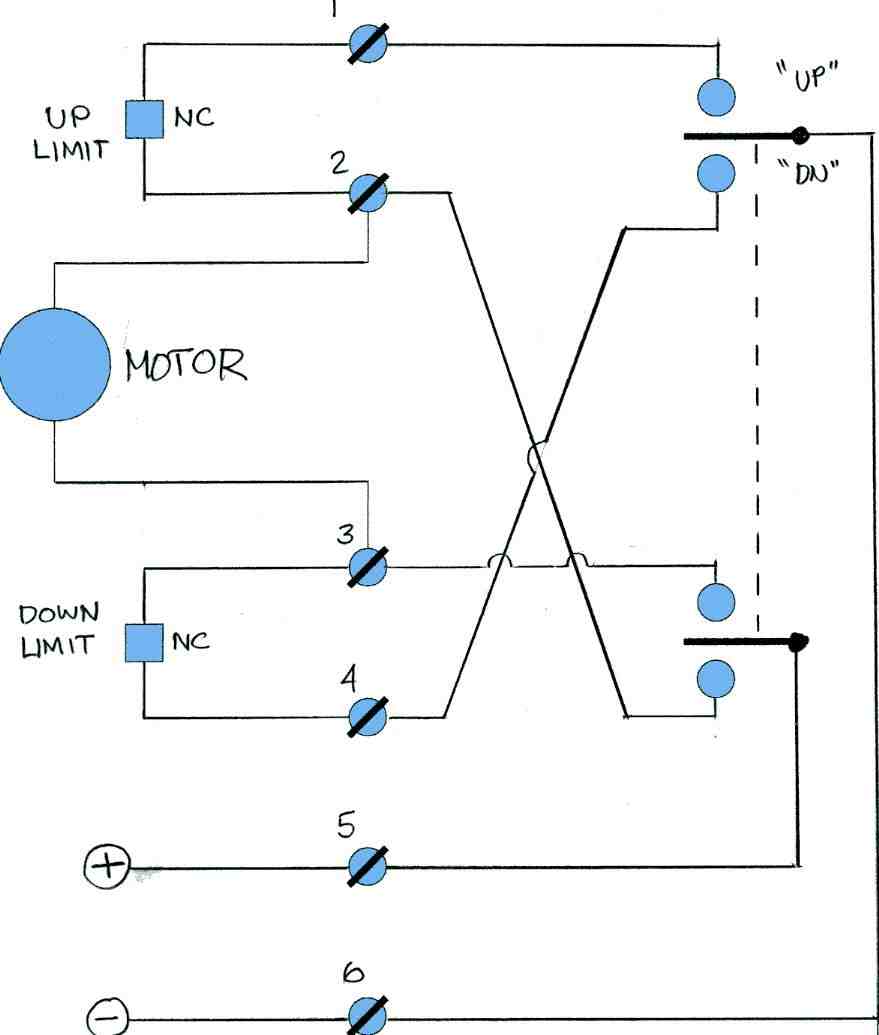

| Here's

the schematic for the rig, a standard motor reversing circuit with

limit switches. The "NC" next to the limit switches means

that

the contacts are "normally closed" when the switch is not being

activated, namely, when the table is not at one of the limits.

When a switch is contacted, it opens, interrupting current of

that particular polarity to the motor. Since the other limit

is

not contacted, reversing the switch reverses the polarity and the motor

can run in the opposite direction . . . until it hits it's limit. |

|

Actually

the

whole thing turned out pretty well, a rare case where a prototype works

better than expected Unfortunately, the framing needed to

support

the regular table isn't sufficient to handle the kind

of

stress that a

cantilevered table can put on it. If I decide to

keep this

basic

design, I'll likely mount the whole thing on a piece of 3/4" cabinet

grade

(ie. flat) plywood and secure this to several more points on the wall.

No matter what, a powered table is the height of convenience when you

find yourself configuring your dinette for sleeping-eating-sleeping

.... etc.