This is easily the most ambitious project to date. Some of the complexity was due to an extensive re-wiring of the front end electrical between the batteries and the new inverter.

Pictured is the original equipment Parallax converter. As you probably know, a converter converts AC shore power (120 volts alternating current) to about 13.8 volts direct current. This is used to run all the standard equipment that comes with the trailer. (Refer, water pump, hot water ignition, if any, lights, etc.) Thus, the converter powers everything DC while hooked up to shore power and recharges the battery at the same time. This is all pretty ok, so long as you don't demand a lot from your batteries (stay frequently at full hook-ups), and you never need AC power to your receptacles when boondocking. The problem is that most converters, and especially this one, don't know much about the care and upkeep of deep-cycle batteries. The technicalities are beyond the scope of this article, and, besides, there are numerous and better sources on the web that explain the intricacies of the subject. Suffice it to say, we decided to “improve” the situation.

The Parallax, shown here without covers, is actually two things in one. The upper section is the load distribution part. The circuit breakers on the left protect the AC equipment and outlets, and on the right, automotive type fuses cover your DC circuits. This is all done up to UL code and works pretty well. The lower part is the converter itself. You can't tell much from here but the converter is pretty crude. That's ok, because it's going to go.

We decided to replace the converter with an inverter/charger. An inverter does the opposite of “convert”. It takes DC and “inverts” it to AC. Thus, an inverter connected to your battery bank, will power your TV or other small AC appliances. I say “small” because, unless you have a really big battery bank, your batteries will deplete very rapidly. This is because most AC appliances use a lot of power compared to the usual DC tasks that need doing in your trailer. But what about re-charging the batteries when connected back on shore power? Our inverter, as do some others, has a very sophisticated charger built right in, one that understands in a highly competent way, how to maintain your batteries. In adddition, it can charge your depleted batteries at a rate of up to 75 amps. This makes short work of recovering from your two or three day boondock.

I forgot to take an outside picture of our inverter but you can find much more at http://www.xantrex.com , the manufacturer's site. Note that, from the guts, you can see it is a very well built piece of equipment with some serious electronics inside. Compare it with the picture, above, of the Parallax.

This inverter is a Marine 15. Go to the site, above, to learn more about these and other members of the Xantrex line. Over the years, this outfit has bought out most of its reputable competitors so that much of what is current inverter technology can be found in one place. They're not cheap but deals can often be found on eBay occasionally and at http://www.store4power.com/. This last site is the refurb outlet for Xantrex and is where we bought ours. Compared to retail, they have some very good prices that average about what eBay deals go for.

In my mind, these inverters have a huge advantage over their simpler cousins. They have an optional monitor/controller panel that is, essentially a micro-computer (these days, what isn't) in a small housing with controls and a digital display on the front. They give you complete access to all inverter/charger functions as well as monitoring battery status and usage. Cool. I found a “Link 1000” unit on eBay for less than half the retail price.

Before we could get started, I needed to figure out the existing wiring. For peace of mind, I decided I needed to know it all, from the front to the conveter. This meant that I had to trace out every wire through the various rats nests to my destination. In all fairness, Bigfoot probably doesn't expect anybody will be doing this so their emphasis is getting the job done ... not necessarily for show. This is an area where a nicer job would assist anyone who has to work on the trailer, and improve the Bigfoot standing in the quality department.

This is where the umbilical (trailer connection) comes up through the floor and into the trailer. The location is behind the under-seat area to the front left. The water heater is visible to the left.

I needed to straighten this out, as much as to know what was going on as to, well, just straighten it out.

This was the result. Now, I know exactly what everything does, and where it is. The gray wire is the power and sense lines going from the inverter to the Link 1000 monitor, headed for the corner, then up inside the corner gusset into the top cabinet. The last picture shows the destination.

The panel I removed came out with a jillion little brads. It goes back in with four screws.

This is what the original “power cabinet” looks like. The lid is normally screwed on, something I rectified (using hinges) about 20 minutes after getting the trailer home from the dealer.

The silver snake is the 3” heater duct for under the table. It was completely in the way until I figured out to just to go over it.

The thick black wire is the 30 amp shore power line that normally is just stuffed through the power hatch from the outside.

We're looking down on the Parallax converter. The shiny part is the upper distribution section. The lower section with the fan is the converter section that will be removed. We gain 3 inches or so of room in doing that.

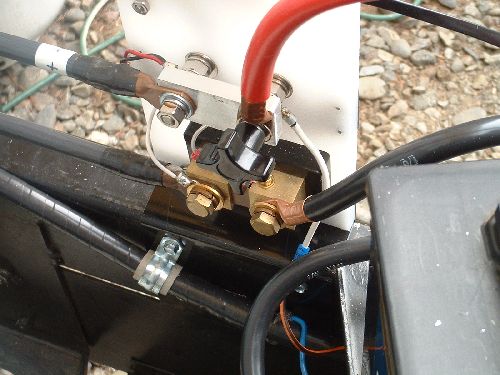

This

is something every Bigfoot

may not have. It's an option that is often packaged along with other

stuff. It's a battery disconnect and is shown here in the original

location in the forward under-seat area against the front wall, tucked

up under the

ledge. The umbilical terminal strip two pictures back is immediately to

the left.

The disconnect relay is controlled by a rocker switch by the front door. I've heard a couple of explanations for this gizmo but the one I think is right is: it's supposed to disconnect the battery line to the towing vehicle so you don't discharge your towing vehicle starting battery while parked and still hooked up. For some reason, this one was wired wrong and disconnected the trailer battery from the trailer. When the switch was off, then the refrigerator and anything else that needed to stay on, was also off. The splices are where I originally connected the refer line direct to the battery to avoid the above.

The fuses are for the main DC (30 amp) service from the battery, then split into one, for the refer, stereo circuit, and CO2/Propane sensor.

By now, I was getting pretty confident as to what everything was, and what I was going to do to it.

I had a 46 lb. Inverter with a footprint of around 12” by 14” that wouldn't fit around the duct. These are 4 x 4 redwood blocks lagged to the floor. On top of these, a piece of 3/8' ply gets screwed for the base of the inverter.